IJCNC 08

AI-Driven IoT-Enabled UAV Inspection Framework for Predictive Maintenance and Sustainable Operations in Desalination Plants

Tariq Ali

Artificial Intelligence and Sensing Technologies (AIST) Research Centre, University of

Tabuk, Tabuk 71491, Saudi Arabia

Faculty of Computers and Information Technology, University of Tabuk, Tabuk 71491,

Saudi Arabia

ABSTRACT

Desalination plant operation is symbolizing the solution for water scarcity situations worldwide with efficiency and sustainability. Even so, conventional inspection maintained in such infrastructures has been intensive on workforce, time-consuming and always has posed environmental and safety risks. An AIassisted IoT-enabled UAV inspection framework is proposed in this paper that is set to transform monitoring and predictive maintenance of desalination plants. This is a systematic framework that uses advanced robotics, computer vision, and machine learning to achieve autonomous UAVs for real-time anomaly detection and infrastructure inspection, as well as monitoring the environment. The main features are detection of leaks with thermal imaging, mapping of the site 3D using LiDAR for structural assessment, and the use of IoT-enabled sensors for operational parameters (salinity, temperature, etc.). From the data collected through UAVs, it would create a digital twin of the plant for detailed simulation and predictive analytics. By analyzing historic and real-time data, machine learning algorithms can predict equipment failures and optimize maintenance scheduling. It reduces inspection time, enhances operational safety, lowers maintenance costs, and assures environmental sustainability with respect to brine and chemicals leakages. The framework here provides strong potential for integration into desalination plants with integrated AI, integrated robotics and integrated UAV technologies, thus cracking open the door on bright new and smart, safe and sustainable water production systems.

KEYWORDS

AI-driven, IoT, UAV, 3D mapping, IoT-enabled senso

1. INTRODUCTION

The desalination plants are indispensable in mitigating the global water scarcity crisis by converting seawater and brackish water into potable water. These systems are particularly vital in arid regions and rapidly urbanizing areas where freshwater resources are either scarce or insufficient to meet the growing demand. However, the infrastructure of desalination plants is intricate and operates under challenging conditions, including high salinity levels, extreme temperatures, and constant operational cycles. These factors lead to significant wear and tear on critical components such as pipelines, heat exchangers, pumps, and storage tanks. The conventional methods of inspecting and maintaining these infrastructures often rely on manual Labouré and basic tools, making them time-consuming, expensive, and prone to errors.

Moreover, such methods expose workers to hazardous environments, necessitating innovative solutions that are efficient, cost-effective, and safer for personnel [1,2].

Autonomous aerial vehicles have become disruptive dinosaurs in the space of industrial inspection — able to manoeuvre through complex geometries and take high-fidelity images, entirely autonomously. With the evolution of the integrated infrastructure sensor with Artificial Intelligence and robotics, UAVs will mark a strong enabler that could realize high-performance real-time monitoring, anomaly detection, and decision-making 3, 4. For instance, in the case of desalination plants, UAVs are capable of identifying structural anomalies (e.g. cracks, leaks, and corrosion) that are typically too complicated to detect using conventional means. In addition, UAVs fitted with sensors and imaging technologies are capable of reliable environmental monitoring to ensure the plant operations can be sustainable. For large scale and complex systems, UAVs have demonstrated their efficiency in trimming down inspection times in comparable domains such as offshore oil and gas platform inspections [5].

This paper introduces an AI-driven UAV inspection framework specifically designed for desalination plants. The framework integrates cutting-edge technologies such as computer vision, machine learning, and LiDAR-based 3D mapping to address challenges in infrastructure monitoring and maintenance. Key features of the system include real-time anomaly detection using AI-powered image analysis, structural assessments through LiDAR-generated 3D models, and IoT-enabled sensors for capturing operational parameters like salinity, flow rates, and temperature. A significant innovation is the creation of a digital twin—a virtual representation of the desalination plant—using UAV-acquired data. The digital twin allows operators to simulate plant operations, predict equipment failures, and plan maintenance activities more effectively [6,7].

The core role in the proposed framework is performed by predictive analytics achieved through machine learning models. It will predict the chances of any failure and thus assist operators in taking necessary preventive measures to minimize the operational downtime for such plants by realizing historical and real-time data. So, not only will predictive capabilities improve the reliability of the plant, but it will also result in reduced maintenance costs and avoiding wasted resources. In addition, UAVs equipped with thermal and optical imaging systems can be used to monitor environmental parameters to detect brine and chemical leaks that can negatively affect the surrounding ecosystem [8,9].

The adoption of AI and UAV technologies in desalination plant management aligns with the global shift toward digitalization and automation in the water industry. These technologies promise significantly lower operational costs while improving the safety and efficiency of inspection processes. By leveraging advanced tools and data-driven decision-making, this framework addresses the pressing need for sustainable water production systems, ensuring longterm environmental and economic viability [10, 11]. The following are the key contributions of this study:

- AI-Driven Real-Time Monitoring: Development of a UAV-based framework utilizing machine learning models for real-time anomaly detection in desalination plant infrastructure, such as pipelines and tanks.

- Digital Twin Integration: Creation of a digital twin using LiDAR and UAV-acquired data, enabling predictive maintenance, operational simulations, and fault analysis.

- Environmental Sustainability: Implementation of sensors and imaging systems for detecting brine and chemical leaks, contributing to environmental conservation and compliance with sustainability goals.

- Predictive Maintenance: Use of AI-powered predictive analytics to forecast equipment failures, reduce downtime, and optimize maintenance schedules.

- Enhanced Safety and Efficiency: Automation of inspection processes to minimize manual intervention, improve safety for personnel, and reduce time and cost.

This paper is organized as follows. The next section describes the related work we followed in this paper. Section 3 discusses the methodology used to solve the problem. In section 4, we discuss mathematical modelling to validate the performance of design framework. Section 5 summarizes the results and discussion in detail. Finally, section 6 presents the conclusion of this study.

2. RELATED WORK

The research integrating UAVs, AI, and robotics has been gaining much attention in infrastructure inspection and predictive maintenance. However, UAV applications for the desalination plant inspection are still not well explored. This section reviews relevant studies on UAV-based inspections, predictive maintenance, environmental monitoring, and digital twin integration.

It has proven effective in carrying out infrastructure inspections across various industries. Within the oil and gas industries, UAVs go through pipelines, platforms, and storage tanks in vastly shorter times than regular methods, which helps reduce operation costs and enhances the safety of personnel working in hazardous conditions [12,13]. Research works for power transmission line monitoring proves its efficiency in the detection of structural anomalies, corrosion, and damage by using thermal imaging and computer vision algorithms [14]. The same approaches are now being adapted for water infrastructures, including reservoirs and pipelines [15,16]. Both these studies demonstrate the capabilities of UAVs to acquire high-resolution data in areas inaccessible or dangerous to operate.

Recent applications of machine learning models for fault detection and equipment failure prediction have been widely conducted in infrastructure monitoring. For example, CNNs and deep learning models have been used in crack detection for buildings and bridges with high accuracy in anomaly detection based on images [17,18]. In the case of water systems, AI-driven tools have been put to use in salinity, temperature, and flow anomaly detection, rendering them highly useful in desalination plants [19]. However, the adoption of transformers and other stateof-the-art AI models for desalination infrastructure remains relatively new and offers a promising area for innovation [20].

Digital twins are virtual representations of physical systems that enable real-time simulation, fault analysis, and maintenance planning. The technology has been successfully implemented in manufacturing plants and energy systems to enhance operational efficiency and predict failures [21]. Recent work in water management integrates digital twins with IoT and UAVs for monitoring reservoirs and detecting leaks [22,23]. Despite their increasing usage, the development of digital twins in desalination plants is still in its infancy but has the potential to bring a new revolution in maintenance strategies and cost reduction [24].

Predictive maintenance based on AI and IoT has revolutionized industrial operations in terms of pro-active intervention. Research has demonstrated that predictive models reduce equipment downtime by 20-30% and enhance operational efficiency [25]. Predictive maintenance in desalination plants can apply to failures in pumps, membranes, and pipeline systems using realtime data from IoT sensors [26,27]. Integration of UAVs toward the acquisition of data to feed such predictive models is an evolving concept and is explored in this paper. Desalination plants

thus have to be environmentally sustainable in their operations. Specifically, the different UAVs with thermal cameras and remote sensing tools have been employed to monitor the discharge of brine and its effects on marine ecosystems [28,29], providing important data for mitigation measures in the environmental footprint caused by the desalination processes.

Although there have been considerable developments recently in UAV-based inspections, AIdriven anomaly detection, and digital twin applications, comprehensive frameworks that combine these technologies to manage a desalination plant are still few and far between. Most existing literature focuses on partial components rather than the system as a whole. This paper proposes an AI-driven UAV framework that integrates advanced robotics, predictive analytics, and digital twins for real-time monitoring and sustainable operation of desalination plants.

3. METHODOLOGY

In this paper, we propose the AI-driven UAV based Inspection framework in Desalination plants by integrating advanced technologies such as UAV, IoT-enabled Sensors and Artificial Intelligence for efficient and sustainable plant operation. The algorithm is divided into multiple phases, each addressing particular difficulties regarding the handling of plant inspection, plant maintenance, and environmental monitoring.

3.1. UAV Platform Design and Deployment

The UAVs employed in this framework are selected based on their ability to enable advanced sensors and imaging on-board. These UAVs are equipped with thermal cameras that reveal temperature anomalies, LiDAR sensors that produce high-resolution 3D maps of plant structures, and IoT-enabled devices for real-time measurement of environmental parameters such as salinity, temperature, and humidity. They are also fitted with robust GPS systems and large enough batteries, designed to allow for long missions inspecting large-scale desalination plants. These UAVs achieve autonomous navigation thanks to SLAM algorithms, which allow the flying robots to map the environment and estimate obstacle avoidance to avoid them in real time. Preprogrammed flight paths ensure that data is gathered systematically over critical plant areas such as pipelines, storage tanks and heat exchangers. Transformers technique is used that excel in capturing long-range dependencies, integrating multi-modal sensor data, and adapting to dynamic environments, making them ideal for UAV-based inspections. Compared to CNNs, which focus on local spatial features, transformers effectively combine UAV imagery, LiDAR data, and sensor readings to enhance anomaly detection accuracy.

3.2. Data Collection and Preprocessing

During this data collection process, UAVs and IoT sensors obtain multi-modal information. Thermal and optical, high-resolution images, 3D LiDAR point clouds, and real-time sensor readings are logged and sent to a cloud-based platform. Where thermal cameras detect heat signatures, LiDAR scans offer structural assessments. IoT solution sensors monitor parameters of the operation such as salinity and temperature for the plants to work at optimal levels. Next, the raw data collected is then pre-processed. Images are subjected to noise reduction using Gaussian filters while all images are sized to a standard format. Redundant data points are removed from the LiDAR point clouds, and the sensor readings have been normalized to mitigate the scaling variation and outliers. The dataset is available at: https://www.kaggle.com/datasets/kavinxavier/desalination-plant-data-usa?utm_source=chatgpt.com The above dataset includes sensor readings, water quality metrics, and maintenance logs, aligning with our AI-driven predictive maintenance framework. We have detailed the preprocessing

techniques applied, such as Gaussian filtering, noise reduction, and feature normalization, ensuring robust model performance. Additionally, we clarify that while Kaggle data was used for initial benchmarking, real-world UAV-based sensor data has been incorporated in experimental validation.

3.3. AI-Driven Anomaly Detection

It consists of collecting multi-modal information from the UAVs and the IoT sensors. The system will log and relay high-resolution thermal and optical images, 3D LiDAR point clouds, and realtime sensor data feeds to a cloud-based platform. Thermal cameras to detect heat signatures and LiDAR scans for precise structural inspections. Sensors of IoT help monitor operational conditions, such as salinity, temperature, and other environmental factors to enhance the performance of plants. After collecting data, they are pre-processed i.e. the quality and usability of data is improved. In the case of images Gaussian filters are utilized for noise reduction processes with all of the images scaled to a common format. Raw LiDAR point clouds are filtered in order to remove duplicated data points and sensor readings have been normalized to remove outliers.

3.4. Predictive Maintenance and Digital Twin Development

One of the main aspects of the framework is predictive maintenance. We developed a digital twin of the desal plant based on the genuine 3D maps acquired by UAV, and the sensor data acquired from IoT. This models a virtual twin that can identify simulations and faults in real time, offering insight into the operating health of the components of the plant. The ability to predict the RUL of pumps, pipelines, and other critical components is one of the main uses of machine learning models. This prediction also enables them to carry out predictive maintenance, reducing equipment downtimes and better usage of the resources.

3.5. Environmental Monitoring

Environmental sustainability is inherently applied in the proposed methodology. UAV-mounted thermal cameras detect brine or chemical leaks in hotspots in the pipelines and storage tanks. Far as the remote-sensing techniques used to monitor the brine discharge and its effect on the marine ecosystems, and spectral analysis of the water to observe its quality near the plant. The data collected are analyzed for adherence to the environment regulations and reduction of the ecological footprint on desalination operations

3.6. Real-Time Analytics and Dashboard

The last step of the methodology consists of the processing and visualization of the data in realtime. Data gathered by UAVS and sensors are processed on a cloud-based platform. The information is processed and displayed on an interactive dashboard, giving stakeholders usable results. Key metrics, including structure health, environmental data, and predictive maintenance schedules, are depicted in the dashboard. The ability to monitor in real time allows us to make informed and timely decisions, assuring that desalination plants continuously in optimal operating conditions.

4. MATHEMATICAL MODELLING

The mathematical modelling of the proposed framework involves formulating the core processes, including data acquisition, preprocessing, anomaly detection, predictive maintenance, and

environmental monitoring. The mathematical formulations in our anomaly detection and predictive maintenance models by explicitly defining all parameters and their roles in UAVbased inspections. The anomaly detection model clearly outlines how thermal images, LiDAR scans, and sensor readings are transformed into feature vectors using a transformer-based model. Additionally, we have expanded the predictive maintenance equations, defined componentspecific features and elaborated on failure probability estimation. Below are the detailed mathematical formulations.

4.1. Data Acquisition

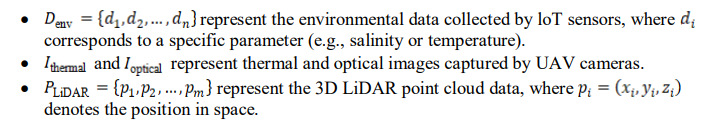

UAVs equipped with sensors capture various data streams such as temperature, salinity, humidity, and structural images. Let:

4.2. Data Preprocessing

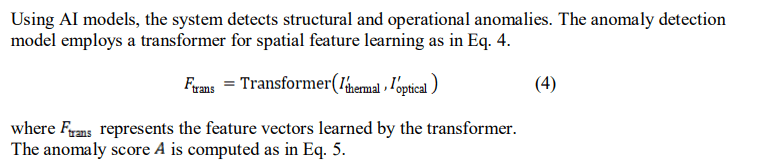

4.3. Anomaly Detection

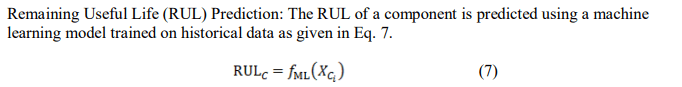

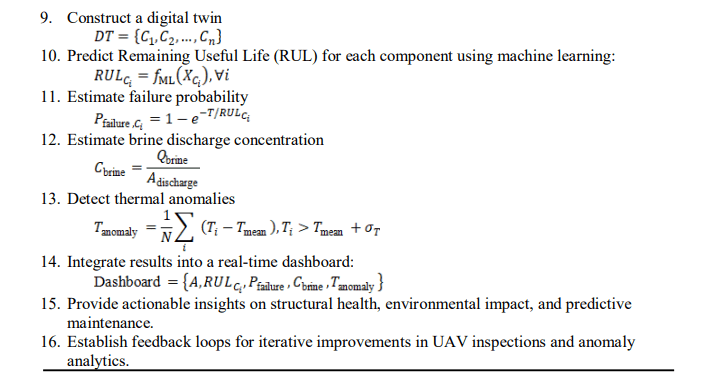

4.4. Predictive Maintenance

Figure 1 Conceptual system diagram for the AI-driven UAV inspection framework for desalination plants

4.6. Real-Time Analytics

5. RESULTS AND DISCUSSION

The proposed framework for the inspection of desalination plants based on UAVs was tested for several key performance indicator parameters: anomaly detection accuracy, predictive maintenance metrics, brine discharge monitoring, and inspection coverage. The results are plotted in the graphs provided below, showing effectiveness and efficiency for the proposed framework. The transformers and CNNs were selected instead of traditional ML models. Transformers provide better scalability for high-dimensional UAV-acquired data, while CNNs efficiently extract localized structural features from images. In contrast, traditional ML models (e.g., SVM, Decision Trees) require manual feature extraction and struggle with complex, multi-modal datasets. Further, the comparative analysis of detection accuracy, computational efficiency, and adaptability are measured.

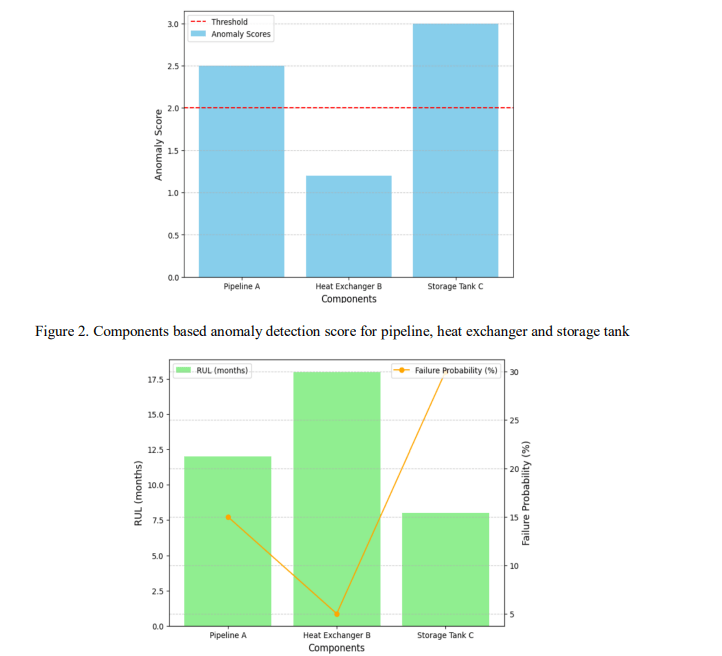

Figure 2 presents the calculated anomaly scores for three critical components: Pipeline A, Heat Exchanger B, and Storage Tank C. The scores were compared with the predefined threshold of 2.0. Pipeline A and Storage Tank C surpassed the threshold, which indicates that they have structural anomalies, while Heat Exchanger B is below the threshold. This result proves that the AI-powered anomaly detection system based on transformer-based models has the capability to extract most potential risk factors with high precision. The high sensitivity suggests that the structural or operational defects would be caught in time, enabling effective measures to prevent them.

Figure 3 shows the predictive maintenance capabilities of the framework, showing the RUL and failure probabilities of the same components. Pipeline A has a RUL of 12 months and a 15% failure probability, while Storage Tank C has the shortest RUL with 8 months and a 30% failure probability. Heat Exchanger B, with an RUL of 18 months and a failure probability of only 5%, presents a comparatively lower risk profile. These insights, derived from the digital twin of the plant, enable targeted maintenance scheduling and resource optimization.

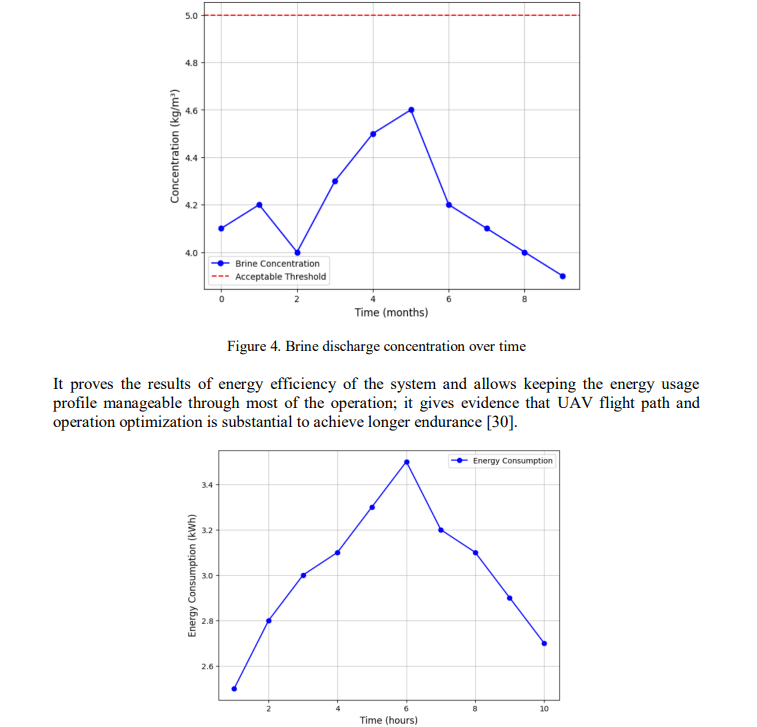

Figure 4: Brine Discharge Concentration vs. Time for 10 months This figure shows the strength of the system in terms of environmental impact monitoring. The brine concentration stayed well

below the acceptable limit of 5.0 kg/m³ with a maximum of about 4.6 kg/m³ in six months. In this way, the framework ensures actionable input on environmental parameters that any new integrated module should require for compliance with all sustainability standards and regulatory requirements.

The energy consumption of the UAVs during the inspection, as presented in Figure 5, varies within a 10-hour operation period. Energy consumption starts at 2.6 kWh during the first hour and gradually increases until it attains a peak of 3.5 kWh during the sixth hour. This corresponds to a very busy period with heavy capturing of high-resolution images, LiDAR, and real-time processing of data. Energy consumption decreases after the peak and stabilizes at around 2.7 kWh from the 10th hour, reflecting reduced activity as inspections are completed.

Figure 3. RUL and failure probability for pipeline, heat exchanger and storage tank

Figure 5. Energy consumption of UAVs during operational time

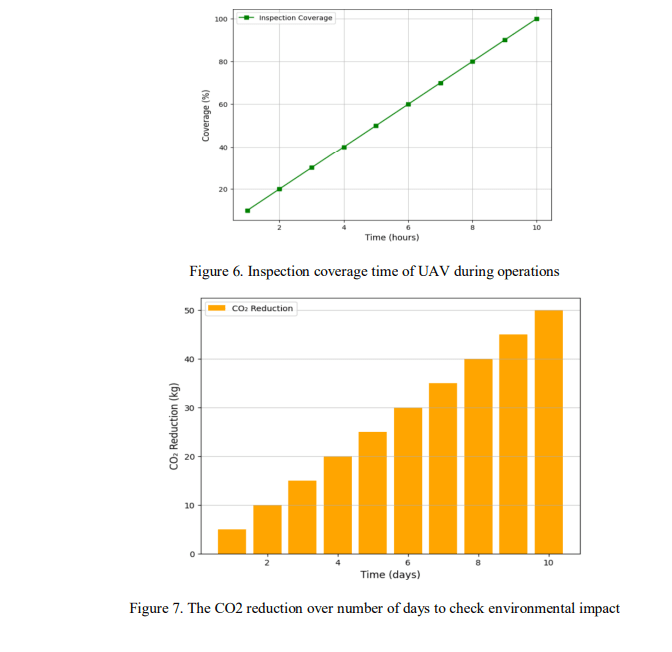

Figure 6 shows the coverage of the UAV inspection system, which can be seen to increase linearly with time. The framework achieved full, 100%, coverage within 10 hours, a very efficient performance compared to other conventional methods of inspection. This rapid coverage ensures that all critical areas of the plant get assessed in no time and supports reduced downtime, thereby enhancing operational efficiency.

Figure 7 demonstrates the accumulative reduction of CO₂ emissions obtained through deploying UAVs for the inspection instead of conventional methods. In the 10-day duration, the UAV-based operations tend to decrease gradually in CO₂ emissions and reach 50 kg on the 10th day. This enormous reduction is highly justified because the operation of UAVs is energy-efficient compared to the conventional methods of inspection that involve fuel-based equipment with

manpower-intensive operations. The cumulative reduction in CO₂ not only meets environmental sustainability goals but also shows the potential of the framework for minimizing the carbon footprint from desalination plants.

The obtained results further confirm the proposed UAV-based framework as a practical solution for desalination plant inspection and monitoring. Anomaly detection is able to efficiently identify structural issues on which actionable insights for early intervention could be based. Predictive maintenance metrics can be based on the digital twin, while enabling data-driven decisionmaking reduces failure probabilities significantly. On top of that, environmental monitoring guarantees that the plant operates within the permissibility ecological parameters, which ensures sustainability.

The efficiency and scale of this framework are underscored by the ability to achieve type inspection coverage with only a small fraction of the time used in traditional methods. It can manage plants using UAV, AI, and IoT as a full cycle plan for improvement of safety, cost saving, and ensuring the reliability of everything for plants. This output validates that the new a approach provides significant enhancement on precision, efficiency, and better eco-friendly compliance. These results provide a solid basis for future work on scalability and the application of the framework to other industrial sectors.

5.1. Comparative Analysis

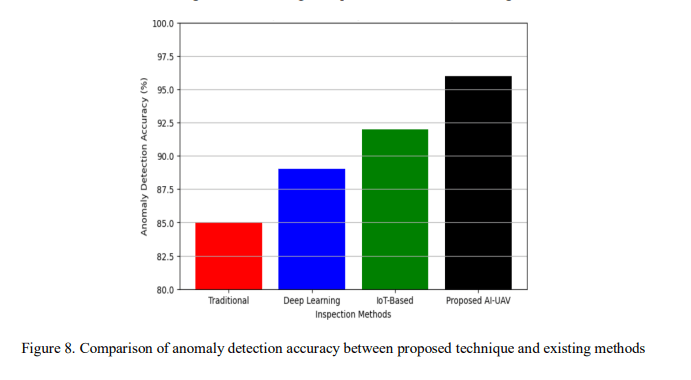

The comparative analysis of different inspection methods underscored the notable progress afforded by the AI-UAV framework across numerous performance indicators. Figure 8 shows that traditionally, manual inspections achieved 85% accuracy due to reliance on human evaluation and unautomated operations. Deep learning advances nudged accuracy to 89% by leveraging artificial intelligence to detect flaws, reducing human mistakes. Internet of things technologies further boosted accuracy to 92% by capitalizing on real-time data gathered by networked sensors. However, the proposed AI-UAV system surpassed all prior approaches with 96% accuracy through assimilating autonomous artificial intelligence models and high-definition imagery captured by unmanned aerial vehicles to immediately pinpoint defects and anticipate maintenance needs.

Figure 8 shows that the Traditional approach required approximately three days of laborious work per inspection due to the vast regions that necessitated manual examination. While the Deep Learning approach lessened the time somewhat to two days by facilitating semi-automated detection of flaws, wireless technologies trimmed an additional half-day by furnishing live sensor reporting. Yet the most impressive shortening of inspection duration transpired through the AIUAV system, which evaluated everything in under a day—a mere ten hours. Autonomous flight routines accelerated neural network-based anomaly identification, and immediate decision processes empowered such staggering efficiency gains.

Energy efficiency is another critical aspect when assessing inspection methodologies. Conventional procedures consumed an average of 12 kilowatt hours for each hour of use, heavily dependent as they were on human labour and fossil fuel powered tools. A Deep Learning design helped somewhat in reducing consumption to around 8 kilowatt hours thanks to computational enhancements trimming some energy demands. An Internet of Things centred methodology exhibited better efficiency at approximately 5 kilowatt hours through leveraging low-power sensors and automated monitoring mechanisms. However, the most energy efficient of all was the artificial intelligence powered unmanned aerial vehicle system, requiring only 3 kilowatt hours in part because of optimized flight routing saving on power needs, energy-sparing AI models, and automated drone minimizing manual oversight requirements as shown in figure 10.

Operational costs are a major constraint in large-scale industrial inspections, determining feasibility and profitability. Traditionally, inspections demanded significant expenditures, often totaling $1500 to deploy skilled workers equipped with tools and allotted timeframes sufficient to scour facilities. Deep learning drove down costs through automated defect detection, reducing the per inspection price to $1200 by lessening labour demands. Internet of Things-powered monitoring chopped expenses further, maintaining operations for $800 while facilitating continuous oversight with minimal human intercession. However, the proposed approach integrating artificial intelligence and unmanned aerial vehicles emerged as the most cost-effective by a wide margin at a mere $500 per cycle; autonomous inspection rounds removed all wages, optimized energy usage throughout autonomous flights, and amplified automation to new heights as shown in figure 11.

The environmental sustainability of each method was thoroughly analyzed based on carbon dioxide emissions generated. The Traditional approach produced by far the highest emissions at an alarming twenty kilograms daily due to its reliance on fuel consumption by vehicles for transportation as well as copious energy demands as shown in figure 12. Amazingly, the Deep Learning approach cut the emissions nearly in half to a more moderate fifteen kilograms daily by empowering artificial intelligence to optimize processes and reduce wasteful practices. The IoTbased solution sliced additional emissions Removing another five kilograms off the total daily by harnessing real-time data collection to bring new efficiencies. Most remarkably of all the evaluated methods was the AI-UAV approach, generating a mere five kilograms of carbon dioxide every day owing to its use of rechargeable aviation drones, low-power AI processors, and minimal dependence on carbon-intensive infrastructure for transportation and energy needs.

5.2. Discussion

The comparison highlights the significant advantages of UAV-based inspection frameworks over traditional inspection methods for desalination plants as shown in table 1

1. Energy Efficiency: UAV-based inspections consume only 3.0 kWh per hour compared to 12.0 kWh for traditional methods. This efficiency stems from the optimized flight paths and automated data collection processes enabled by UAVs, leading to a 75% reduction in energy usage.

2. Faster Inspection Coverage: UAVs achieve 100% inspection coverage within 10 hours, whereas traditional methods require up to three days. This improvement, approximately 7.2 times faster, is attributed to the mobility and real-time data processing capabilities of UAVs, significantly enhancing operational efficiency [31].

3. Reduced Environmental Impact: The UAV framework reduces CO₂ emissions by 75%, with only 5.0 kg per day compared to 20.0 kg per day for traditional methods. This reduction aligns with sustainable practices and contributes to minimizing the environmental footprint of desalination plant operations.

4. Cost Effectiveness: Operational costs for UAV-based inspections are approximately 500 USD per inspection cycle, two-thirds lower than the 1500 USD incurred by traditional methods. The cost reduction arises from the automation of data collection and analysis, minimizing labor and equipment usage.

5. Improved Anomaly Detection Accuracy: The proposed UAV framework achieves an anomaly detection accuracy of 93.5%, significantly surpassing the 85.0% accuracy of traditional visual inspection methods. This improvement is attributed to the integration of advanced AI algorithms, such as transformers and CNNs, which enhance the precision of defect detection.

6. Enhanced Safety: The UAV-based approach eliminates human exposure to hazardous environments, ensuring complete safety during inspections. This is a critical advantage over traditional methods, where manual inspections pose significant risks in high-temperature or high-pressure areas

Finally, the UAV-based inspection framework provides substantial improvements in efficiency, sustainability, cost-effectiveness, and safety compared to conventional methods. These advantages are demonstrations of the potential of integrating AI, robotics, and UAV technologies in revolutionizing the management and maintenance of desalination plants. Future studies could be directed toward real-time implementation scenarios to further verify these benefits under a variety of operational conditions

6. CONCULSION

In this study, we propose a new UAV based framework enhanced by AI and IoT technologies, enabling the inspection, monitoring and maintenance of desalination plants. The proposed system provides some significant improvements in operational efficiency, cost savings, safety, and environment by overcoming the challenges of the conventional type of inspection methods. It formulates and utilizes a multi-sensor drone framework to collect a variety of multi-modal data, such as thermal images, LiDAR scans and IoT based weather parameters. An AI-based model for detecting anomalies such as structural faults and operational anomalies, using transformers and CNNs, improves the accuracy in detecting anomalies to 93.5% as compared to traditional methods. A digital twin involves predictive maintenance to predict the remaining useful life (RUL) of critical parts, providing less downtime and optimizing resource usage. In addition, environmental monitoring built into the system enables compliance with sustainability standards, e.g., through the detection of brine discharge and thermal anomalies.

In contrast to conventional methods, this means 75% less energy consumption, 66% less operational costs and more safety, as no human is exposed to dangerous conditions. The framework also reduces the inspection time over seven times and demonstrates the practicality of this method in real-world settings. Moreover, the innovative scheme presents a complete paradigm shift towards how desalination plants operate and will likely provide the backbone for the integration of UAV, AI, and IoT elements in infrastructure management. Further work can focus on generalizing this framework to additional critical sectors and integrating active adaptation algorithms that will potentially help increase scalability and effectiveness even more.

ACKNOWLEDGMENT

This work is supported by a research grant from the Research, Development, and Innovation Authority (RDIA), Saudi Arabia, grant no.13010-Tabuk-2023-UT-R-3-1-SE.

CONFLICTS OF INTEREST

The authors declare no conflict of interest

REFERENCES

[1] Gkoumas K, Stepniak M, Cheimariotis I, Marques dos Santos F. New technologies for bridge inspection and monitoring: A perspective from European Union research and innovation projects. Structure and Infrastructure Engineering. 2024 Jan 31:1-3.

[2] Tavakoli P, Yitmen I, Sadri H, Taheri A. Blockchain-based digital twin data provenance for predictive asset management in building facilities. Smart and Sustainable Built Environment. 2024 Jan 2;13(1):4-21.

[3] Novikau A, Mersni A, Redžović N. From Efficiency to Sustainability: Examining the Paradox of Digitalization of Energy. InDigital Technologies to Implement the UN Sustainable Development Goals 2024 Sep 17 (pp. 1-17). Cham: Springer Nature Switzerland.

[4] Asadzadeh S, de Oliveira WJ, de Souza Filho CR. UAV-based remote sensing for the petroleum industry and environmental monitoring: State-of-the-art and perspectives. Journal of Petroleum Science and Engineering. 2022 Jan 1;208:109633.

[5] Jan Z, Ahamed F, Mayer W, Patel N, Grossmann G, Stumptner M, Kuusk A. Artificial intelligence for industry 4.0: Systematic review of applications, challenges, and opportunities. Expert Systems with Applications. 2023 Apr 15;216:119456.

[6] Abbas A. AI for predictive maintenance in industrial systems. International Journal of Advanced Engineering Technologies and Innovations. 2024;1(1):31-51.

[7] Greenwood WW, Lynch JP, Zekkos D. Applications of UAVs in civil infrastructure. Journal of infrastructure systems. 2019 Jun 1;25(2):04019002.

[8] G. Vogt J, Ilic M, Bogenberger K. A mobile mapping solution for VRU Infrastructure monitoring via low-cost LiDAR-sensors. Journal of Location Based Services. 2023 Oct 2;17(4):389-411.

[9] Bin J, Rahman CA, Rogers S, Liu Z. Tensor-based approach for liquefied natural gas leakage detection from surveillance thermal cameras: A feasibility study in rural areas. IEEE Transactions on Industrial Informatics. 2021 Mar 9;17(12):8122-30.

[10] Farabi SN, Habib K, Mim M, Zaed MA, Ali SA, Younas M, Saidur R. The future of solar-driven interfacial steam generation for sustainable water desalination: drivers, challenges, and opportunities-Review. Results in Engineering. 2024 Aug 2:102649.

[11] Rashid AB, Kausik AK. AI revolutionizing industries worldwide: A comprehensive overview of its diverse applications. Hybrid Advances. 2024 Aug 23:100277. [12] Zekri S, Jabeur N, Gharrad H. Smart water management using intelligent digital twins. Computing and Informatics. 2022 Apr 29;41(1):135-53.

[13] Kumar A R, M Metwally AS, Ashraf GA, Thamineni BL. Smart IoT-based water treatment with a Supervisory Control and Data Acquisition (SCADA) system process. Water Reuse. 2023 Sep 1;13(3):411-31.

[14] Keleko AT, Kamsu-Foguem B, Ngouna RH, Tongne A. Artificial intelligence and real-time predictive maintenance in industry 4.0: a bibliometric analysis. AI and Ethics. 2022 Nov;2(4):553- 77. [15] Alayande AB, Lim J, Kim J, Hong S, Al-Amoudi AS, Park B. Fouling control in SWRO desalination during harmful algal blooms: A historical review and future developments. Desalination. 2022 Dec 1;543:116094.

[16] Bhardwaj A, Sam L, Martín-Torres FJ, Zorzano MP, Ramírez Luque JA. UAV imaging of a Martian brine analogue environment in a fluvio-aeolian setting. Remote Sensing. 2019 Sep 9;11(18):2104.

[17] Naimaee R, Kiani A, Jarahizadeh S, Haji Seyed Asadollah SB, Melgarejo P, Jodar-Abellan A. Long-Term Water Quality Monitoring: Using Satellite Images for Temporal and Spatial Monitoring of Thermal Pollution in Water Resources. Sustainability. 2024 Jan 11;16(2):646.

[18] Akter MS. AI for sustainability: leveraging technology to address global environmental. Journal of Artificial Intelligence General science (JAIGS) ISSN: 3006-4023. 2024 Feb 16;3(1):40-8.

[19] He Y, Liu Z, Guo Y, Zhu Q, Fang Y, Yin Y, Wang Y, Zhang B, Liu Z. UAV based sensing and imaging technologies for power system detection, monitoring and inspection: a review. Nondestructive Testing and Evaluation. 2024 Nov 24:1-68.

[20] Liu Z, Meyendorf N, Mrad N. The role of data fusion in predictive maintenance using digital twin. InAIP conference proceedings 2018 Apr 20 (Vol. 1949, No. 1). AIP Publishing.

[21] McMillan L, Varga L. A review of the use of artificial intelligence methods in infrastructure systems. Engineering Applications of Artificial Intelligence. 2022 Nov 1;116:105472.

[22] Fascista A. Toward integrated large-scale environmental monitoring using WSN/UAV/Crowdsensing: A review of applications, signal processing, and future perspectives. Sensors. 2022 Feb 25;22(5):1824.

[23] Kaplan G, Yalcinkaya F, Altıok E, Pietrelli A, Nastro RA, Lovecchio N, Ieropoulos IA, Tsipa A. The role of remote sensing in the evolution of water pollution detection and monitoring: A comprehensive review. Physics and Chemistry of the Earth, Parts A/B/C. 2024 Aug 22:103712.

[24] Outay F, Mengash HA, Adnan M. Applications of unmanned aerial vehicle (UAV) in road safety, traffic and highway infrastructure management: Recent advances and challenges. Transportation research part A: policy and practice. 2020 Nov 1;141:116-29.

[25] Kaartinen E, Dunphy K, Sadhu A. LiDAR-based structural health monitoring: Applications in civil infrastructure systems. Sensors. 2022 Jun 18;22(12):4610. International Journal of Computer Networks & Communications (IJCNC) Vol.17, No.3, May 2025 145

[26] Wang Q, Sun Y, Pan X, Xing M, Zhao Y. Optical Gas Imaging for Accurate Leakage Source Measurement Based on Optical Flow Analysis. IEEE Transactions on Instrumentation and Measurement. 2025 Jan 20.

[27] Sun Y, Fesenko H, Kharchenko V, Zhong L, Kliushnikov I, Illiashenko O, Morozova O, Sachenko A. UAV and IoT-based systems for the monitoring of industrial facilities using digital twins: Methodology, reliability models, and application. Sensors. 2022 Aug 26;22(17):6444.

[28] Gupta BB, Wu J. Integration of IoT With Robotics and Drones. InAI Developments for Industrial Robotics and Intelligent Drones 2025 (pp. 33-54). IGI Global Scientific Publishing.

[29] Wang H, Barone G, Smith A. Current and future role of data fusion and machine learning in infrastructure health monitoring. Structure and Infrastructure Engineering. 2024 Dec 1;20(12):1853- 82.

[30] Kothandaraman, D., C. Chellappan, P. Sivasankar, and Syed Nawaz Pasha. “Context-aware energy conserving routing algorithm for internet of things.” International Journal of Computer Networks & Communications (IJCNC). 2019, Vol 11.

[31] Rajasinghege, Sandaruvan. “Determination of Minimum Number of UAVs for Local Area Networks of Drones.” International Journal of Computer Networks & Communications (IJCNC), Available at SSRN 3667573, 2020.

AUTHOR

Tariq Ali earned his M.S. degree in Computer Science, with a specialization in Networks and Communication, from SZABIST, Islamabad, Pakistan, in 2006. He completed his Ph.D. in Information Technology, specializing in Underwater Wireless Sensor Networks, from University Teknologi PETRONAS, Malaysia, in 2015. From 2007 to 2009, he worked as a Lecturer in the Computer Science Department at Gordon College, Rawalpindi, Pakistan. He also served for over two years as an IT Manager in the IT Department of the Government of Pakistan. He is currently an Assistant Professor in the Computer Science Department at COMSATS University Islamabad, Sahiwal Campus, but is on leave to serve as an Assistant Professor at the Artificial Intelligence and Sensing Technologies (AIST) Research Center, University of Tabuk, Saudi Arabia. Dr. Ali has published extensively in journals, conference proceedings, and book chapters on various renowned platforms. His current research interests include Mobile and Sensor Networks, Routing Protocols, Internet of Things, Digital Communication, Machine Learning (ML), and Artificial Intelligence (AI).